- Home

- Case Studies

- Ootmarsum

Location

Ootmarsum, Netherlands

Start-up

October 2007

System

Airlift MBR

Capacity

Rain water flow, 150 m3/h (fluxes up to 65 l*m-2*h-1)

Dry weather flow, 75 m3/h (fluxes up to 55 l*m-2*h-1)

background

Waterschap Regge en Dinkel, a Water Board in the East of Holland, has realized an innovative Hybrid MBR for treating municipal wastewater at the WWTP Ootmarsum.

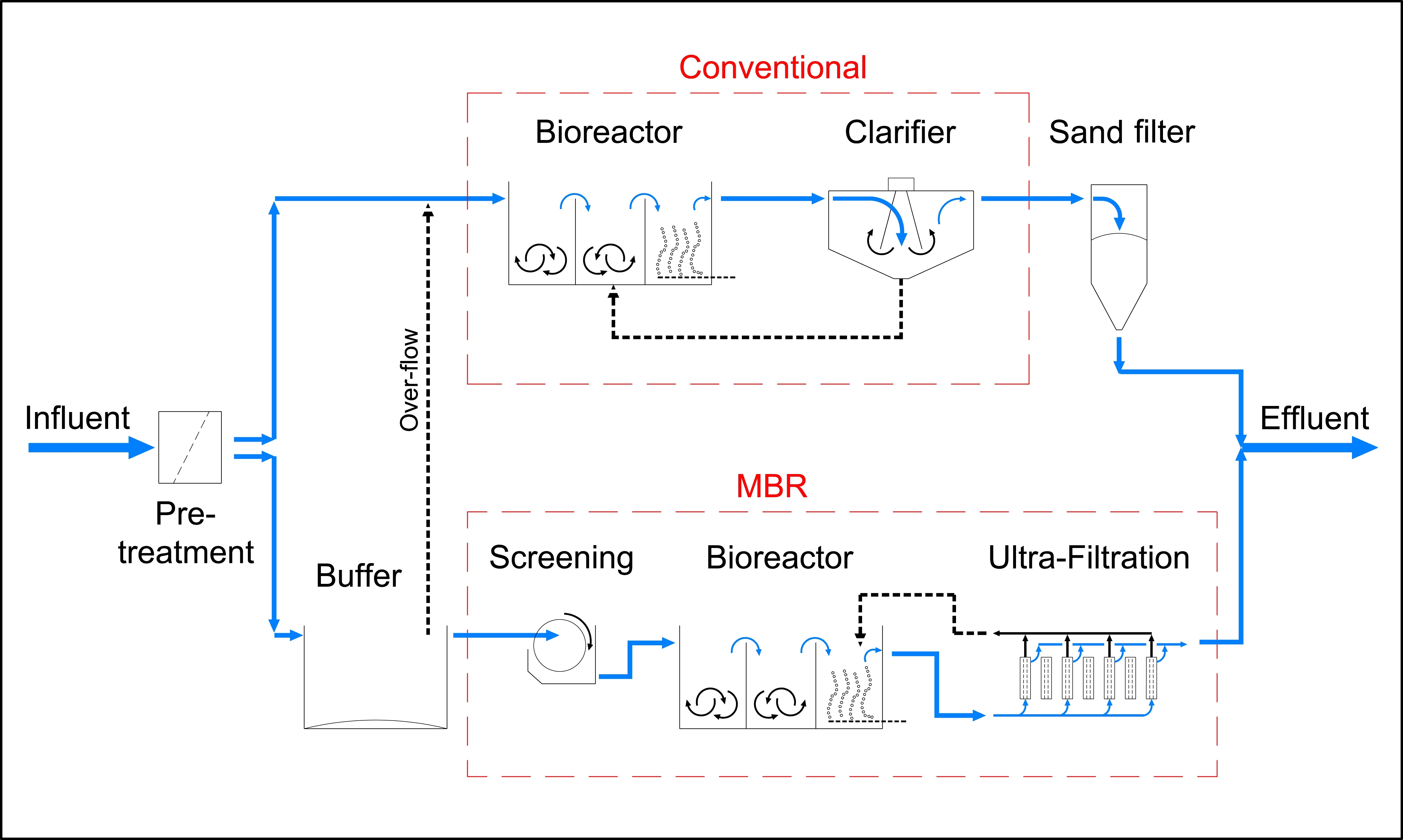

The hybrid systems combines conventional biological treatment, followed by sandfiltration with membrane bioreactor treatment as shown below in the schematic overview.

The Airlift membrane unit is delivered by Pentair. The MBR was successfully commissioned in October 2007 and the actual performance of the bioreactor and the UF installation are both above expectation.

Reasons to choose the Airlift™ MBR technology were:

- robust and reliable system

- low energy and chemical

- consumption

- dry solution (side stream)

- closed system, easy to clean

- fully automated

- high water quality

- small footprint

Image flow chart

scope of supply

84 x Compact 33V – 5.2 mm UF membrane

5 x Airlift Solution

1 x Airlift Solution executed with 12 Helix membranes since February 2015

airlift mbr

Airlift MBR is a compact built purification system combining the biological degradation (biological N and P removal) step with UF separation placed outside the bioreactor. In the UF membranes, activated sludge is circulated over the modules combined by continuous aeration controlling the cake formation, while permeate is extracted at the permeate side. The Airlift system is a cost-effective method for treating municipal wastewater in a clean setup.

Application area

High mixed liquor suspended solids (MLSS) streams, up to 15,000 mg/l.

Main application

Municipal/ low industrial polluted wastewater treatment plants.

System lay-out

Airlift MBR systems are available as standardized, modular skids. The modules are placed vertically resulting in a reliable and compact installation.

Related products

The Compact 33V is a tubular 5.2 mm ultrafiltration membrane module for use in AirLift™ MBR process or in cross-flow installations, for separating oil and sludge from water.