GET SPINNING WITH HELIX

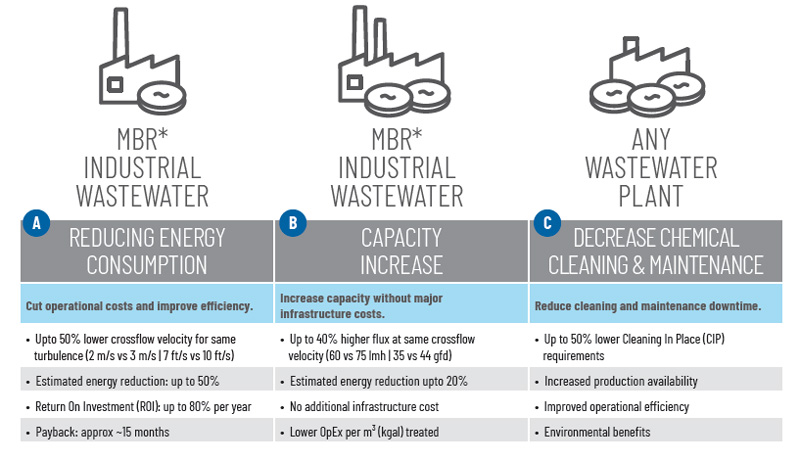

Our patented Helix Technology offers a revolutionary membrane filtration solution that generates turbulence at the membrane surface, effectively minimizing fouling and particle buildup. This innovation not only enhances operational efficiency but also significantly reduces maintenance costs and chemical usage.

Upgrading your existing tubular membranes with Helix Technology can lead to substantial cost savings and improved efficiency, whether you choose to upgrade early, mid-life, or at the end of the membrane's lifecycle.

ADRESSING UF BOTTLENECKS

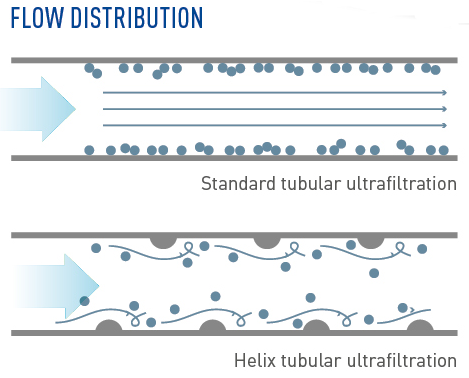

High-solids ultrafiltration (UF) faces bottlenecks due to foulant buildup, leading to reduced flux, lower flow, and increased energy consumption.

Helix tubular membranes:

- Introduces turbulence at the membrane wall: Continuous mixing removes the cake layer.

- Improves hydraulic permeability: Enhances flux and flow, increasing productivity and reducing costs.

- Lowers energy footprint: More efficient than smooth tubular membranes.

Minimize Fouling, Maximize Efficiency

HELIX VS SMOOTH TUBULAR MEMBRANES

BENEFITS

- Retrofit easily to save on equipment and labor costs, with flexibility, minimal downtime, and maintained productivity.

- Increases productivity and lowers energy consumption

- Less downtime of wastewater plant due to fouling prevention capability.

- Trust our decades of industry experience for reliable, high-quality solutions.

CASE STUDY - PERFORMANCE COMPARISON

Pentair initially installed two units with six X-Flow Compact 27 membrane elements for leachate treatment. Six standard elements in one unit were replaced with Compact 27 Helix membrane elements. Flux increased from 135 lmh for standard Compact 27 to an impressive 180 lmh with the Compact 27 Helix membrane module. This results in energy savings of around 33 percent.

| Technology: | Crossflow MBR | |

| Crossflow velocity: | 3.5 m/s | |

| UF feed water: | 10 – 15 g/l MLSS | |

| Energy saved: | 33,3% |