PRODUCT INFORMATION

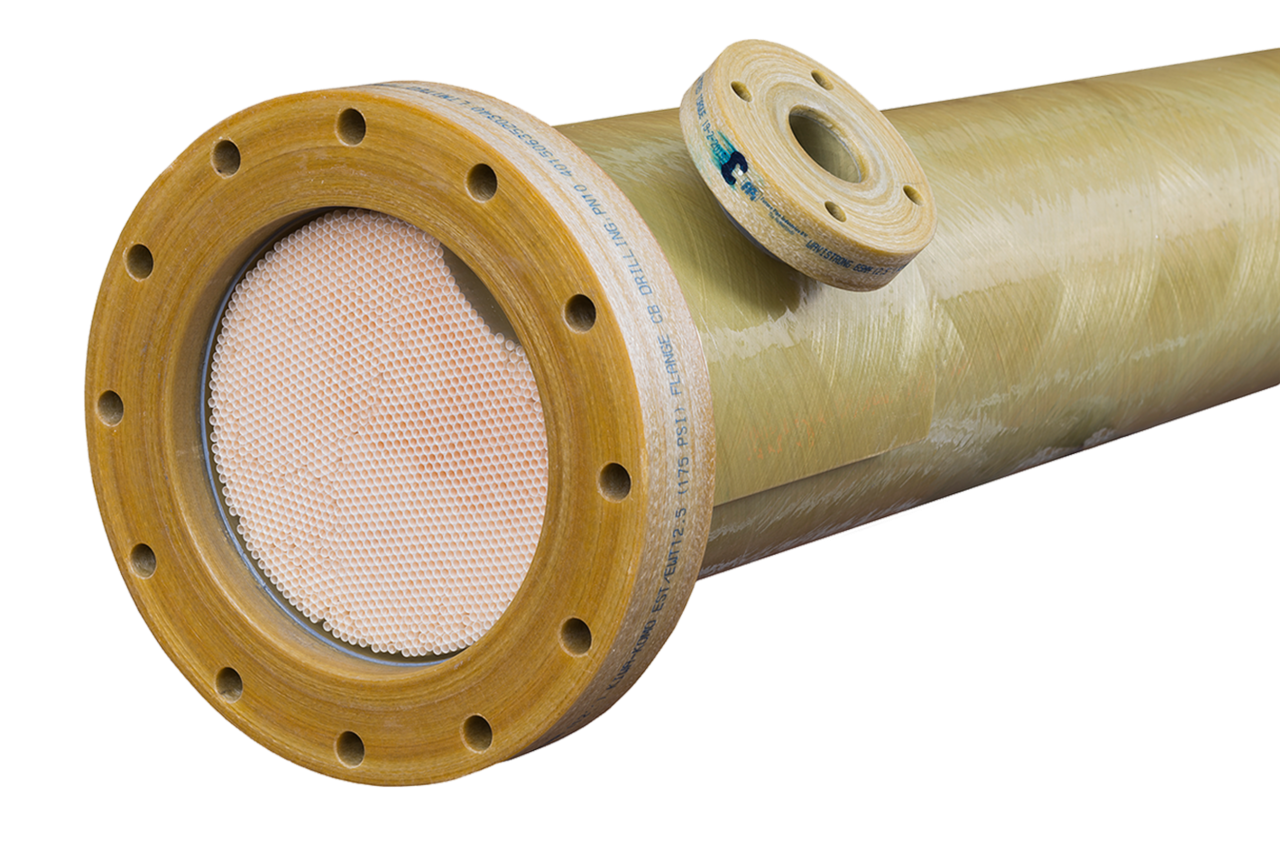

The Compact 75G is the largest member of the X-Flow Compact family. A 12” glass fibre reinforced module fit for extreme challenges such as Produced Water Treatment. Through its unique design the Compact 75G is limiting construction costs and maximizing its output. The core of the Compact 75G are the proven X-Flow tubular UF membranes, with a mean pore size of 30 nm.

- med1

- med2

FEATURES

- Hydrophilic tubular polyvinylidene

- Fluoride membrane cast on a polyestercarrier

- Structure asymmetric

- Mean pore size of 30 nm

- Developed for use in large-scale processes for water purification

- High performance and a very good antifouling behaviour

- Membrane elements can be backflushed for efficient membrane cleaning resulting in a higher average product flux

- Also available with the X-Flow Helix technology, to enhance flux and herewith performance by providing enhanced mixing and efficient removal of the cake.

-

FUNCTIONAL DESCRIPTION

-

X-FLOW COMPACT 75G MEMBRANE MODULES

The Compact 75G is a X-Flow tubular UF membrane with a mean pore size of 30 nm.

Key specifications

- Temperature range: 0-50°C

- Maximum operating pressure: 6 bar

-

FIELDS OF APPLICATION

-

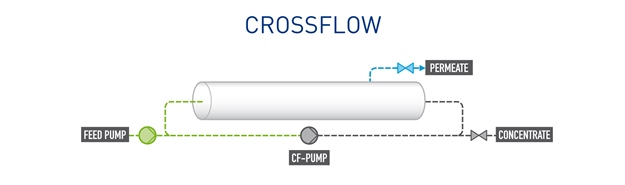

The X-Flow Compact 75G is developed for large-scale waste water treatment of reuse projects. Its robust design make the module the workhorse of the X-Flow Compact Family and particularly fit for applications such as large scale MBRs and the treatment of (waste)water that comes up with the oil from the well during production (Produced water treatment). Oil is extracted from deep underground wells, sometimes up to four kilometers deep. During the oil extraction, water is co-produced. Unfortunately for the oil companies co-producing this water is inevitable.

It can be concluded that water has a significant impact on any oil company’s operations. Reuse of produced water therefore makes sense, especially if this can further increase oil production. By treating this water with the Compact 75G all suspended solids and all free/emulsified oil is removed and the water is desalinated by Reverse Osmosis membranes. This illustrates that a (water) waste problem can be converted into higher oil production.

SPECIFICATIONS - LARGE SCALE

| COMPACT 75G HELIX | |

| Membrane surface area | 75 m² |

| Module dimensions (dxl) | 12 inch x 3070 mm |

| Housing material | Glass fibre reinforced epoxy |

| Membrane material | PVDF |

| Hydraulic membrane diameter | 5.2 mm |

| Nominal pore size | 30 nm |

| pH-range | 1-11 |

| Chlorine resistance | 300.000 ppm.hrs |

| Helix technology | Yes |

Replacement: in case you have Compact modules, you can find your replacement alternative on the replacement page.

Helix technology: read more on our Helix technology page.

SPECIFICATIONS - SMALL SCALE

| COMPACT 75G NON CODED | |

| Membrane surface area | 33 m2 |

| Module dimensions (dxl) | 8 inch x 3000 mm |

| Housing material | PVC-C |

| Membrane material | Reinforced PVDF |

| Hydraulic membrane diameter | 5.2 mm |

| Nominal pore size | 30 nm |

| pH-range | 1-11 |

| Chlorine resistance | 250.000 ppm hours@ ph >10 |

Connection configurations: to learn more about other X-Flow membrane modules and their connection configurations, please click here.