PRODUCT INFORMATION

X-Flow HFS60 modules are based on hydrophilic hollow-fiber ultrafiltration membranes, composed of a PES/modified PES blend. The membranes, which are operated in a dead-end mode, have high mechanical and chemical strength, making them suitable for a wide range of applications. The pressurized membrane modules with inside-out configuration are the industry’s choice for the removal of colloids such as colloidal silica.

FEATURES

- Removal of colloidal matter: 99,8% removal of colloidal silica.

- High membrane packing density: the industry's smallest free volume in a membrane module.

- 100% integrity testing on individual fibers.

- Individual fiber repair.

- Very good antifouling behavior.

- Typical permeate quality:

- SDI < 3.

- Turbidity < 0.1NTU.

- Excellent chemical resistance with a wide pH range (1-12) and high chlorine stability (maximum free chlorine 250 mg/l).

- Typical high permeability: low energy consumption.

-

FUNCTIONAL DESCRIPTION

-

Pretreatment for silica removal

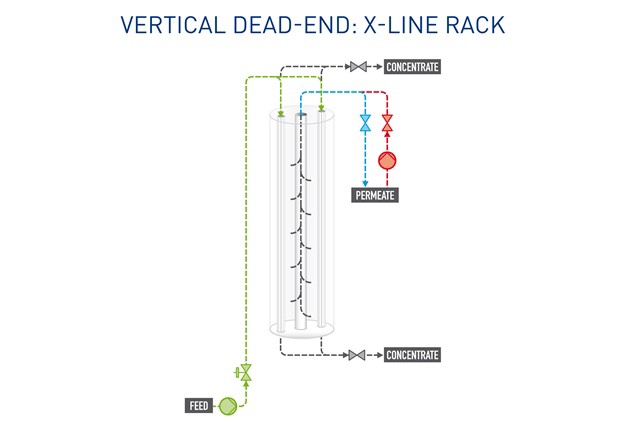

The core of the HFS60 membrane technology is the single-fiber, inside-out filtration process that delivers a robust solution. The modules are operated vertically and can be configured in four different ways:

- In the X-line rack

- With standard end caps.

- In the vertical high-pressure setting.

- In the horizontal dead-end UF configuration.

Click here to learn more about these three configurations.

-

FIELDS OF APPLICATION

-

Silica removal in demin plants

The HFS60 membrane modules will remove colloidal silica in boiler feed applications. The HFS60 membrane can either be installed downstream or upstream of the demin plant. When installed downstream of the demin plant, the HFS60 membranes can be operated at high fluxes and with long cleaning intervals. When installed upstream, they will not only remove colloidal silica but also suspended solids and microbial particles, thus providing excellent protection of the ion exchange system.

Soft drink manufacturing

The HFS60 membrane meets the 20 kDa requirement for soft drink manufacturing. It guarantees the best water quality, free from microbial particles, suspended solids, and small colloidal matter that may interfere with the manufacturing of soft drinks (such as carbonated drinks, iced tea, and packaged water).

SPECIFICATIONS - Large Scale

| HFS60 | |

| Membrane surface area | 60 m² |

| Module dimensions (dxl) | 8.7” x 1.54m |

| Housing material | PVC |

| Membrane material | PES/MOD PES |

| Hydraulic membrane diameter | 0.8mm |

| Pore size | 10,000 Dalton |

| pH-range | 2-12 |

| Chlorine resistance | 250,000ppm hours @ pH ≥10 |

SPECIFICATIONS - Small Scale & Piloting

| R-21 HFS | RX-300 HFS | |

| Membrane surface area | 4.0m2 | 0.07m2 |

| Module dimensions (dxl) | 3” x 1m | 1” x 0.3m |

| Housing material | PVC-C | PVC |

| Membrane material | PES/MOD PES | PES/MOD PES |

| Hydraulic membrane diameter | 0.8mm | 0.8mm |

| Pore size | 10,000 Dalton | 10,000 Dalton |

| pH-range | 2-12 | 2-12 |

| Chlorine resistance250,000ppm hours @ pH ≥10 | 250,000ppm hours @ pH ≥10 |