- med1

- med2

- med3

- med4

FEATURES

- Aerobic wastewater treatment

- Municipal wastewater

- Low strength industrial wastewater

- Enchased side stream UF

- Small footprint

- Minimal pre-treatment requirements

- Low TCO

-

TYPICAL USE

-

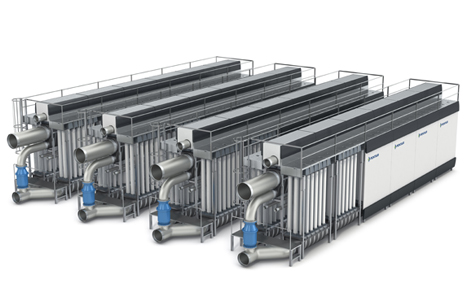

Pentair X-Flow Airlift Solution delivers a cost-effective membrane bioreactor (MBR) solution for municipal and industrial wastewater treatment applications. Synergize the crossflow filtration principle at low velocities enhanced with the Airlift process to create sufficient turbulence to solve cake layer build-up and operate at high flux rates. The X-Flow Airlift solution eliminates the build-up of debris at the membrane inlet with the drain step.

Be assured of effective cleaning of the membranes and easy maintenance with Pentair X-Flow sidestream membrane bioreactor solutions. The X-Flow Airlift Solution requires a small footprint and lowers the total cost of ownership compared to the submerged MBR systems.

-

SCOPE

-

Airlift uniquely combines membranes with biological treatment. With carefully selected partners for the biological part, Pentair develops innovative and ready-to-use membrane installations that meet both regulatory and financial KPI’s.

With world-class X-Flow Membrane Solutions and Pentair X-Flow Membrane+ Approach, you’ll gain peace of mind. Delivering what you and your customers strive for – treating low and medium strength wastewater and producing high-quality filtrate in bioreactor applications.

-

FIELDS OF APPLICATION

-

The need for reusing wastewater, both industrial and municipal, requires top quality membranes which provide directly reuseable water. The ultrafiltration membranes applied can be compared to those used in drinking water plants. Energy consumption is at the level of submerged membrane systems or lower, due to the efficient use of process conditions for flux enhancement.

Another major advantage of the Airlift technology is that the membrane modules are placed outside the bioreactor in a clean and dry setup. The wastewater itself is inside the membranes rather than outside, thus eliminating the problem of maintaining modules submerged in activated sludge. The membranes are easily accessible and cleaned.

For capacities >7,5 MLD the application of our Airlift Megablock can be of interest.

RELATED X-FLOW MEMBRANE ELEMENT

The related membrane element for this technology is shown below.

The Compact 33V is a tubular 5.2 mm ultrafiltration membrane module for use in AirLift™ MBR process or in cross-flow installations, for separating oil and sludge from water.

To view all our X-Flow membrane elements click here.

XF33R is a tubular 3 mm ultrafiltration membrane module for use in Airlift MBR process installations, for separating oil and sludge from water.