- media 1

- media 2

- media 3

Features

X-Flow membranes can be used for:

- Biological waste water treatment

- Water recycling and reuse

- Color removal

- Wine and cider filtration

- Beer filtration

- Filtration processes in dairy industry

- Dairy filtration

-

TYPICAL USE

-

The water that is going to end up in the products of Food & Beverage manufacturers has to be safe and of consistent quality. Destined for critical consumers, the water has to contribute to health and wellbeing, and cannot be allowed to cause variations in taste and other product characteristics. Most F&B manufacturers are very aware of the risks involved, and many rely on point of entry barriers for consistent water quality. Point of entry barriers are typically installed just behind the water meter, at the point where the water mains enters the building.

Ultrafiltration (UF) technology provides an effective barrier against all kinds of contaminants, and peace of mind for manufacturers who have reason to be concerned about the quality of their mains water. Absolute certainty about the water that will be part of your products also depends on the integrity and cleanliness of the plumbing behind the point of entry barrier.

-

SCOPE

-

As one of the world’s foremost membrane technology knowledge centers, we share our scientific know-how and practical experience with our partners to make the difference in challenging filtration projects.

Our services during start-up and commissioning to ensure flawless color removal are unique in the market and will help to meet or exceed all expectations.

-

FIELDS OF APPLICATION

-

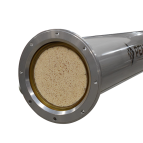

R100

R100 is a stainless steel membrane elements used for the filtration and clarification of aqueous solutions and beverages such as wine, juice and cider. With feed-and-bleed operation in crossflow mode with regular backwashes, the R100 membrane elements offers continuous (unmanned) operation and excellent throughput, eliminating the use and disposal of kieselguhr (diatomaceous earth): no CO₂ loss, no oxidation, no color loss, and no product loss with high recoveries of over 98 percent. Adjusting the filtration to different types of wine is relatively easy, and the wine quality is much less dependent on the staff than it is with diatomaceous earth.

R30

R30 membrane elements are usually racked in a skid (standard unit) of 6 elements. The permeate flow ranges between 1200-2400 liter per hour per element, which amounts to 7.5-15 m3 per hour per skid. The mode of operation is typically batch-wise, but continuous operation by alternation between two sets, or cascade systems, are also possible.

P170A

P170A membrane element is a microfiltration insert used in the food and beverage industry. For example for the separation of milk proteins and plant based proteins. It is known for its added value in product quality and taste, production costs, and environmental impact.

BMF

Pentair‘s Beer Membrane Filtration System - BMF establishes a sustainable brewing process and a matching working environment void of the health and safety risks that were present in the Diatomaceous Earth (DE) era of filtration. And since the goal is to produce the best and most constant beer quality, one cannot overlook BMF’s measurable improvement to the beer’s taste and colloidal stability.

TITLE DOWNLOAD PDF

Beer Membrane Filtration Brochure DOWNLOAD

Related X-Flow membrane elements

The related membrane elements for this technology are shown below.

To view all our X-Flow membrane elements click here.

R100

The Pentair X-Flow R100 microfiltration Membrane Element has been the chosen method of filtration for wines, wine must, juices, milk, vinegar and beer.

The Pentair X-Flow P170A Membrane Element is a microfiltration insert used in food & beverage industry. For example for the separation of milk proteins and plant based proteins.

R30

The R30 membrane modules deliver a superior filtration method in the production of food & beverages, including beer, wine, cider and milk.