- med1

- med2

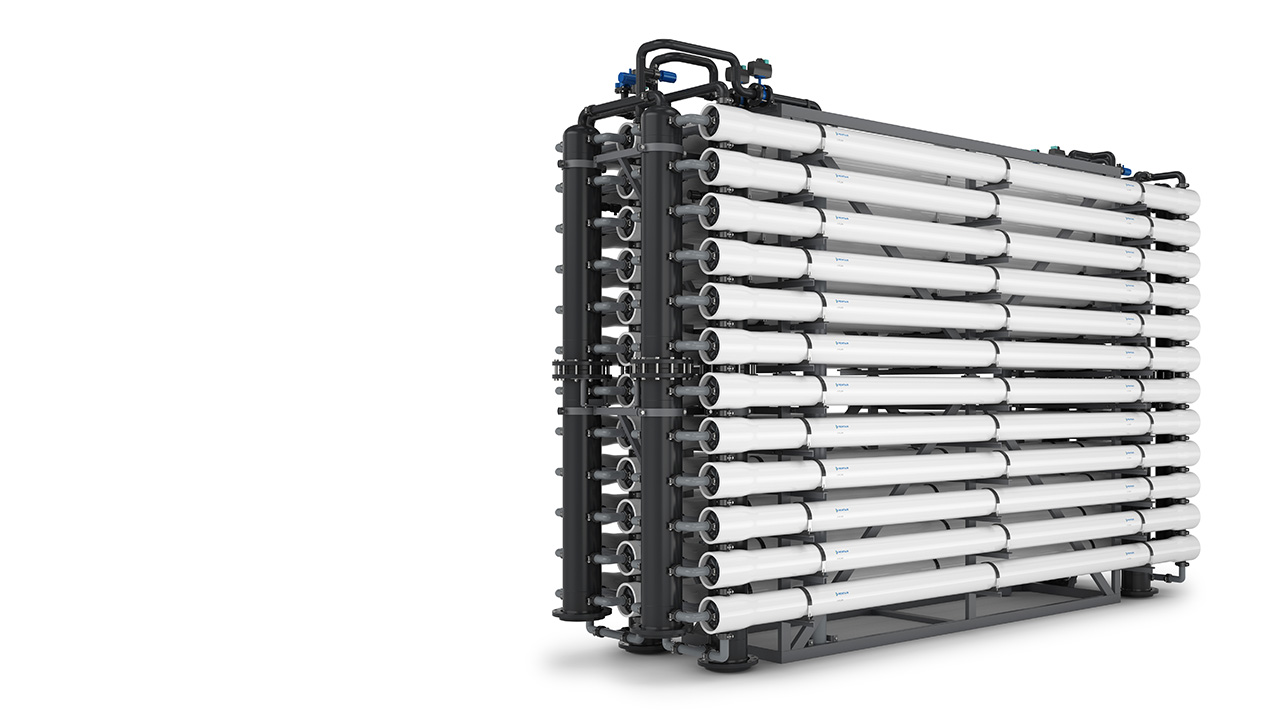

FEATURES

- Highest membrane area-to-footprint ratio in the market

- Up to four membrane elements can be placed in one GRP housing

- Operating pressure up to 8 barg

- Suitable for inline operation

- High reference base, used in multiple large ultrafiltration (UF) plants around the world

- Direct filtration of all water sources

-

TYPICAL USE

-

Pentair X-Flow Xiga Solution ensures a minimum membrane footprint for surface water, groundwater, seawater, and wastewater treatment requirements compared to other ultrafiltration systems. Installed in glass reinforced plastic membrane housings, it facilitates the UF system to deliver up to 20 barg to operate inline with the downstream reverse osmosis (RO) system. Eliminate the intermediate break tank by reducing the capital investment that makes an ideal configuration for large desalination projects.

Pentair X-Flow ultrafiltration membranes tackle feed water fluctuations and consistently removes suspended solids, salt density index causing particles, colloids, bacteria, and viruses. With upfront direct coagulation, ultrafiltration membranes reduce the color and dissolved organics to meet stringent water-quality requirements.

-

SCOPE

-

With carefully selected partners, Pentair develops innovative and ready-to-use membrane installations that meet both regulatory and financial KPIs.

With world-class X-Flow Membrane Solutions and Pentair X-Flow Membrane+ Approach, you’ll gain peace of mind.

Delivering what you and your customers strive for – an ultrafiltration solution for water treatment and wastewater reuse with low total cost of ownership

-

FIELDS OF APPLICATION

-

Xiga is developed for the treatment of surface water (to produce potable water or process water) and drinking water. It it also applicable for wastewater polishing and reuse. As pretreatment for seawater RO, it has a very impressive reference base. Xiga is also applied in industries such as Oil & Gas (injection water production).

It is the industries’ solution of choice when it comes to potable water, process water or polishing applications.

Based on your feedwater characteristics and flow requirements, our specialist can determine the optimum solution for your specific challenge.

FEATURED CASES

RELATED X-FLOW MEMBRANE ELEMENTS

The related membrane elements for this technology are shown below.

The Pentair X-Flow XF64 Membrane Element is used for the production of process and potable water from surface water, for wastewater polishing and reuse, in the pre-treatment of large SWRO plants, and in large-scale drinking water production.

To view all our X-Flow membrane elements click here.

The Pentair X-Flow XF75 Membrane Element is used for the production of process and potable water from surface water, for wastewater polishing and reuse, in the pre-treatment of large SWRO plants, and in large-scale drinking water production.