- Home

- Our Technology

- Reverse Osmosis

REVERSE OSMOSIS PRETREATMENT

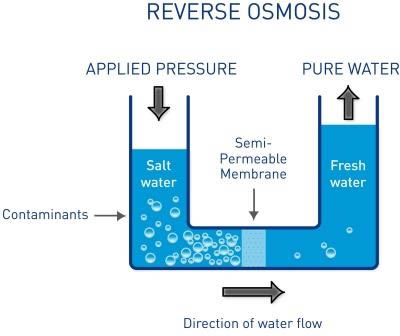

Reverse osmosis has been used for over decades to remove impurities from water by retaining solvent molecules on a semi-permeable membrane.

Molecular-Size Particles

Reverse osmosis filtration is one of the few methods that can remove molecular-sized particles, such as ions and bacteria. By applying external pressure higher than the solution's osmotic pressure, the natural process of osmosis is reversed, achieving separation.

Past to Future

The success of reverse osmosis membrane technology began with extensive research. Today, it is used in nearly every application to purify water, from industrial wastewater decontamination to preparing drinking water from various sources.

Membrane Materials

Different types of RO membranes are available to address various water contaminants. Most are made from polymers like cellulose acetate or TFC polyarmtic compounds, providing the high structural and chemical stability that has made RO membranes the preferred choice worldwide.

Versatility

RO membrane systems vary in size from personal, bottle-sized purifiers to large-scale desalination and industrial water treatment plants, which Pentair X-Flow helps to build globally.

Interested in finding out what products we have for pretreatment of RO? Check our Filtration Spectrum.

In case you have any questions please contact us.